Invest in your health by controlling your blood sugar and weight, decreasing inflammation, and improving brain and heart function with Cocoa Powder.

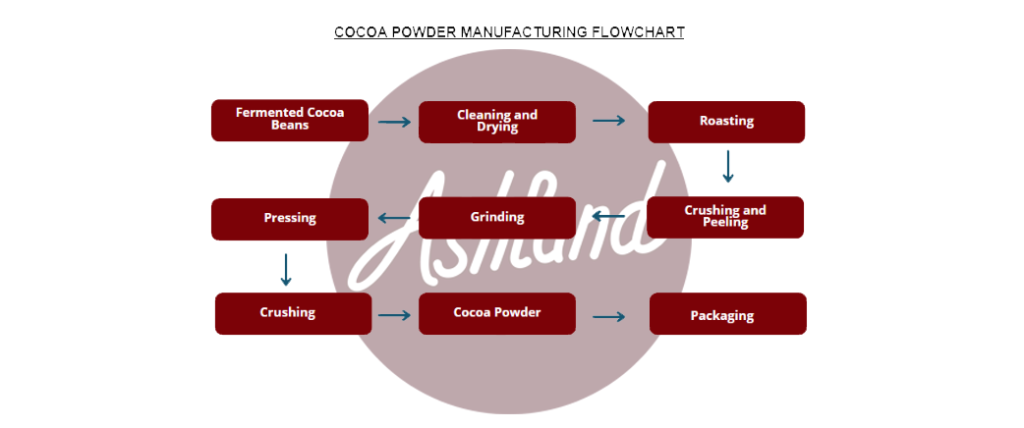

Cocoa powder, the magical ingredient that infuses our baked goods, confections, and beverages with irresistible chocolate flavor, has a fascinating journey from cocoa beans to your kitchen. At Ashland Cocoa, we take immense pride in the craftsmanship and precision that goes into creating the cocoa powder we offer. In this article, we invite you to embark on a journey with us as we explore how cocoa powder is meticulously processed from cocoa beans.

Step 1: Harvesting Cocoa Pods

The journey begins with the harvesting of cocoa pods. Cocoa trees (Theobroma cacao) bear colorful pods, each containing cocoa beans. These pods are carefully harvested by skilled farmers when they reach maturity, typically twice a year. Ashland Cocoa have our own cocoa plantation in Sulawesi, Indonesia. We also collaborate with cocoa farmers from Africa to produce our premium cocoa powder.

Step 2: Fermentation

Once harvested, the cocoa beans are extracted from the pods and placed in shallow containers or wooden boxes. Fermentation is a crucial step in the cocoa bean processing journey. During fermentation, the beans are exposed to the natural elements and microorganisms, which initiate a series of chemical changes that develop the cocoa’s flavor. This process can take several days and is a key factor in determining the flavor profile of the final cocoa powder.

Step 3: Cleaning & Drying

After fermentation, the beans are spread out in the sun to dry. This step is essential for reducing the moisture content of the beans to a level suitable for further processing. Proper drying and cleaning is critical to prevent mold and ensure the beans’ quality.

Step 4: Roasting

Once dried, the cocoa beans are roasted to enhance their flavor. Roasting is a carefully monitored process that brings out the characteristic chocolate aroma and deepens the cocoa’s color. The specific roasting parameters, such as temperature and duration, can vary depending on the desired flavor profile.

Step 5: Crushing and Peeling

After roasting, the cocoa beans are cracked open to remove the outer shell, leaving behind the cocoa nibs.

Step 6: Grinding

These nibs are then ground into a paste called cocoa liquor or cocoa mass. This paste is rich in cocoa solids and cocoa butter.

Step 7: Pressing

The cocoa liquor is pressed to separate the cocoa solids from the cocoa butter. This process yields two distinct products: cocoa cake (which is further processed into cocoa powder) and cocoa butter.

Step 8: Crushing/Milling for Powdering

The cocoa cake is milled into a fine powder to create cocoa powder. This milling process reduces the cocoa solids into small particles, resulting in the familiar texture and consistency of cocoa powder.

Step 8: Packaging and Quality Control

The final cocoa powder is carefully inspected for quality and consistency. It is then packaged in airtight containers to preserve its freshness, flavor, and aroma.

Conclusion:

The journey of cocoa powder from cocoa beans is a testament to the craftsmanship and dedication of cocoa farmers and processors alike. At Ashland Cocoa, we understand the significance of every step in this intricate process, and we are committed to sourcing the finest cocoa beans and employing the most meticulous processing methods to ensure that you receive the highest-quality cocoa powder for your top business.